| Model |

Flow |

Inlet and Outlet |

Dimensionmm |

Weight |

Heater Power |

Blower Power |

| m³/min |

DN |

L |

W |

H |

Kg |

kW |

kW |

| ZDB800 |

12 |

50 |

1450 |

960 |

2180 |

1750 |

9 |

1.6 |

| ZDB1250 |

18.5 |

65 |

1600 |

1200 |

2300 |

1950 |

12 |

2.2 |

| ZDB1850 |

27.5 |

80 |

1850 |

1200 |

2400 |

2600 |

12 |

2.2 |

| ZDB2200 |

32.5 |

80 |

1900 |

1280 |

2450 |

2850 |

18 |

4 |

| ZDB2950 |

44 |

100 |

2200 |

1350 |

2510 |

3150 |

24 |

5.5 |

| ZDB3350 |

50.3 |

100 |

2350 |

1450 |

2530 |

3400 |

27 |

7.5 |

| ZDB4000 |

60 |

125 |

2420 |

1500 |

2625 |

4000 |

27 |

7.5 |

| ZDB5000 |

76 |

125 |

2500 |

1550 |

2700 |

5400 |

36 |

8.5 |

| ZDB6000 |

100 |

150 |

2850 |

1960 |

2550 |

6700 |

45 |

8.5 |

| ZDB7500 |

124 |

150 |

3050 |

2500 |

2650 |

8500 |

54 |

12.5 |

| ZDB9500 |

152 |

200 |

3500 |

2600 |

2750 |

11250 |

65 |

12.5 |

| ZDB13000 |

208 |

200 |

3680 |

2700 |

2750 |

14000 |

115 |

22 |

| ZDB15000 |

250 |

250 |

4020 |

2800 |

2800 |

15000 |

130 |

30 |

| ZDB20000 |

300 |

250 |

4300 |

2900 |

2850 |

17600 |

140 |

30 |

* Final dimensions and weights may vary slightly depending on the actual situation

Correction Factor

| Work Pressure (BarG) |

4.5 |

5 |

6 |

7 |

8 |

9 |

10 |

| Correction factor |

0.679 |

0.748 |

0.874 |

1.000 |

1.126 |

1.252 |

1.380 |

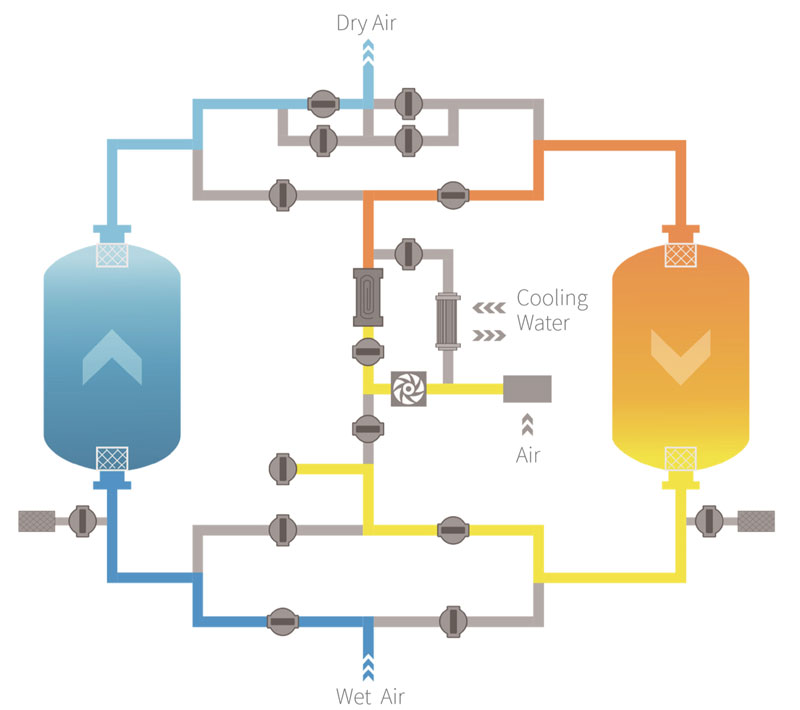

Operating conditions

√ Inlet temperature:≤38℃

√ Ambient temperature:1-45℃

√ Standard Working Pressure:0.7Mpa

√ Power:AC380V/3P/50Hz

√ Cooling Water: ≤32℃

Standard configuration

√ PDP:-40℃

√ Adsorbent life:3 years

√ Valve with Stainless Steel Core

√ PLC Control,Color screen

√ Dewpoint display and energy saving module

√ Valve position monitoring

Optional configuration

√ Galvanized or stainless steel pipe

√ Communication telex function

√ High temperature and high pressure intake

√ Tower insulation

ZDC Heat Of Compression Zero Purge Desiccant DryerDetails

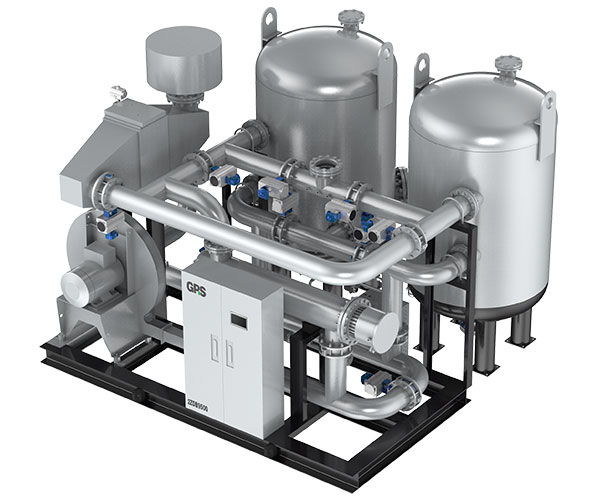

ZDC Heat Of Compression Zero Purge Desiccant DryerDetails ZDB Blower Zero Purge Desiccant DryerDetails

ZDB Blower Zero Purge Desiccant DryerDetails ZDB+ Blower Zero Purge Desiccant DryerDetails

ZDB+ Blower Zero Purge Desiccant DryerDetails ZDC-SF Double Intake Heat Of Compression Zero Purge Desiccant DryerDetails

ZDC-SF Double Intake Heat Of Compression Zero Purge Desiccant DryerDetails ZDC+ Superior Heat Of Compression & Blower Zero Purge Desiccant DryerDetails

ZDC+ Superior Heat Of Compression & Blower Zero Purge Desiccant DryerDetails