- DRUM DRYER

-

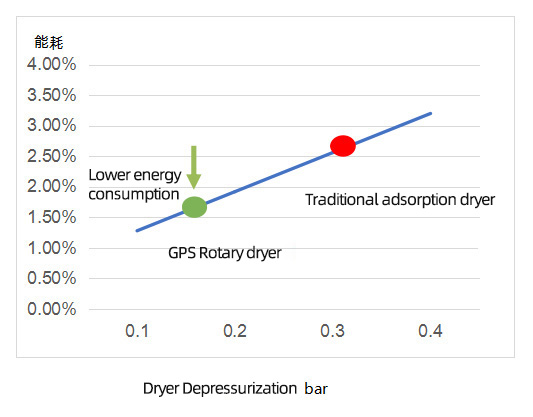

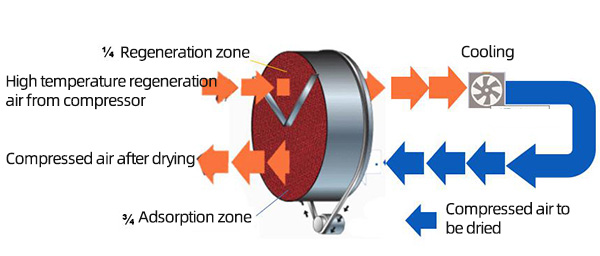

ZERO PURGE DESICCANT DRYER

-

ZDC Heat Of Compression Zero Purge Desiccant DryerDetails

ZDC Heat Of Compression Zero Purge Desiccant DryerDetails -

ZDB Blower Zero Purge Desiccant DryerDetails

ZDB Blower Zero Purge Desiccant DryerDetails -

ZDB+ Blower Zero Purge Desiccant DryerDetails

ZDB+ Blower Zero Purge Desiccant DryerDetails -

ZDC-SF Double Intake Heat Of Compression Zero Purge Desiccant DryerDetails

ZDC-SF Double Intake Heat Of Compression Zero Purge Desiccant DryerDetails -

ZDC+ Superior Heat Of Compression & Blower Zero Purge Desiccant DryerDetails

ZDC+ Superior Heat Of Compression & Blower Zero Purge Desiccant DryerDetails

-

- DESICCANT DRYER

- AIR TREATMENT SYSTEM

- PARTS AND SERVICE